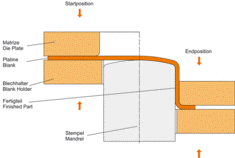

Deep-drawing

Deep-drawing is a manufacturing process in which a cut to size even plate is placed and centred into a tooling. The blank is pressed on a hold-down device by a pulling die which also holds it at the outer edge. The hold-down device impinged with pressure is suppressed by a die which is impinged with higher power and pulls the plate over the bevelled edge into the pulling die, thus a hollow part arises. The bottom of the vessel keeps its original thickness of plate while the edge of the work piece is stretched and, therefore gets slightly thinner. In case that the required depth of the bowl cannot be realized by a single deep-drawing process, it is possible to divide the entire process into several operations.

Generally, nearly all metallic materials can be formed by deep-drawing as, for example:

- Non-corrosive steels, e.g. 1.4301 / 1.4404 / …

- Aluminum and aluminum alloys

- Sheet steels

- Heat-treatable steels

- Fine-grained steels

- Titanium and titanium alloys

- Nickel and nickel alloys

- Tantalum, zircon, niobium

Advantages:

- constant repeatable production quality

- after approval short processing time

- nearly constant wall thickness

Production possibilities:

- deep-drawing parts 4500 x 2500 mm

- drawt depth up to 600 mm

- press capacity up to 2500 t