FSW: Friction Stir Welding

How it works

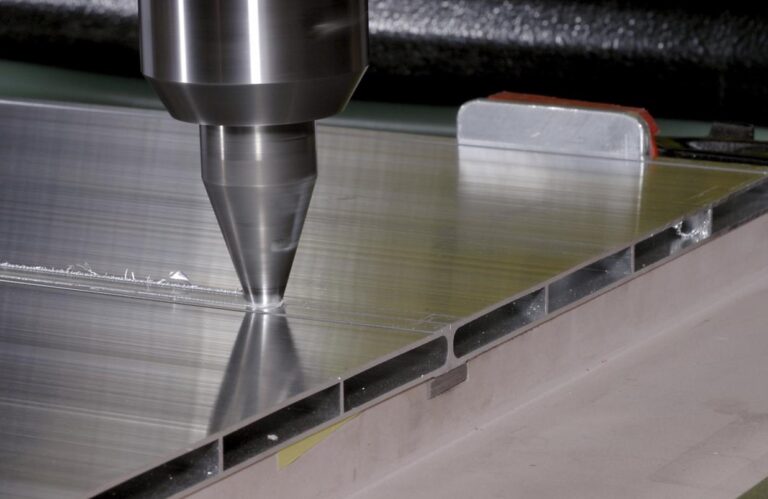

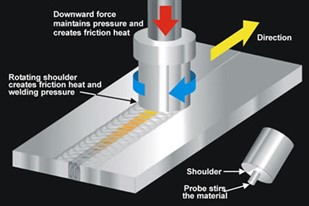

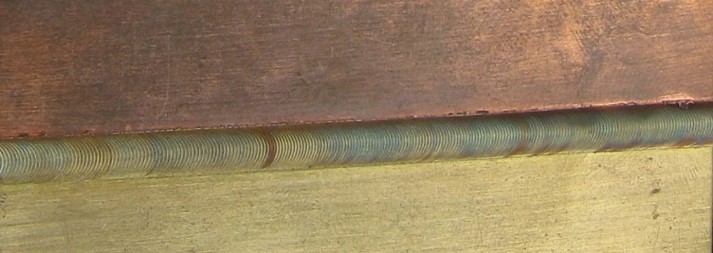

Friction Stir Welding is an innovative solid-state joining technology. The connection or weld is created by means of a rotary tool, consisting of a pin with a special profile. The material is heated by friction to a temperature at which the material is in the plastic state. FSW is a welding process where the melting temperature is not reached.

Friction stir welding is particularly suitable for joining materials with a low melting point such as aluminum, brass, copper, titanium …

If the thickness is less than 2 mm, we are speaking of micro-FSW. In this case, a higher rotation speed and precise positioning of the work pieces is required. The lower limit for the thickness is around 0.3 mm.

Benefits

Friction Stir Welding FSW provides the main advantages in industrial manufacturing:

- High welding speed

- Economic process

- High mechanical characteristic

- Heterogeneous welding in various materials (Aluminum, copper, light alloys…)

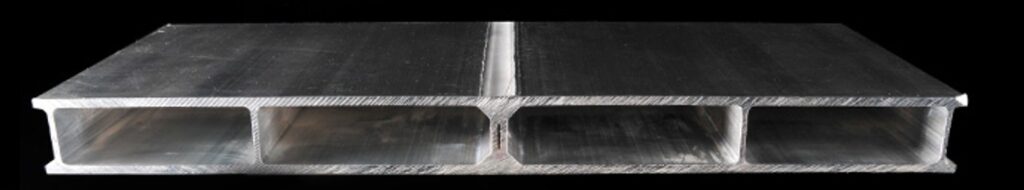

- High-thickness welding up to 100mm in one pass

- No consumables…

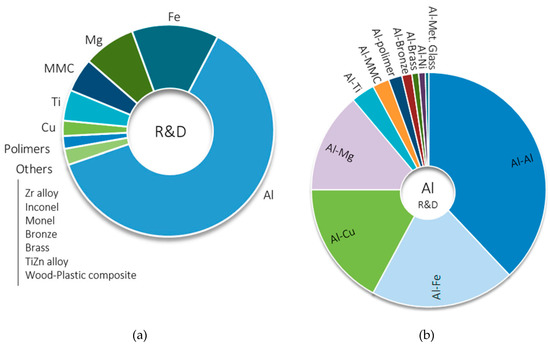

Materials

Friction Stir Welding can bring interesting solutions. We can easily weld homogenous multiple materials: Aluminum, Steel, Copper, Titanium, etc. But also a combination of heterogeneous materials in various conditions like Al/Al (2XXX/7XXX, 7XXX/6XXX…), Al/Steel, Al/Cu, Al/Mg, Al/Ti.

We can count on a qualified research team that can help you in exploring the best solutions for your application through design and prototype testing.

Services

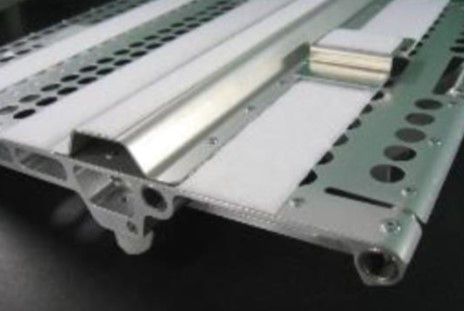

We’re your partner in sub-contracting, providing FSW technology together with all its advantages.

We specialize in the production of single pieces, small and medium size batches on our FSW machines.

Starting from drawings, we guide our customers through the process to obtain the best quality FSW solution. Flexibility and quality are the key elements towards our clients.

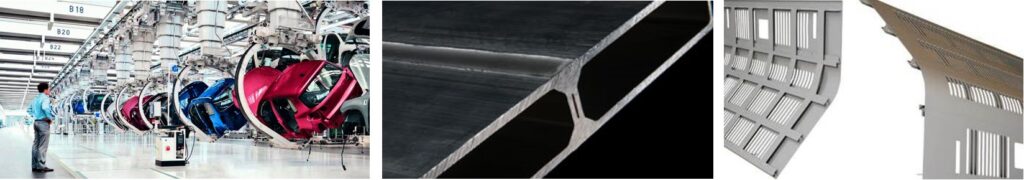

We weld parts for a differentiated group of clients and sectors like alimentation, petrochemicals, transport, pharmaceutics, military, pneumatics, construction, metals, engineering,…

In case you need more information feel free to contact us.

Product Engineering & Prototyping

Thanks to our in-house design team, customers’ demands for products design can be supported in the most effective and highest quality in a short lead time.

Our research, quality and manufacturing capacities also enable us to do prototyping for big and important projects.

Machines

At the moment, we can offer welding solutions on several types of Friction Stir Welding (FSW) machines with position and force control along with other specific features :

- Table machines Serie TS for R&D applications.

- Machine 30kN, table size 800x600x500mm, thickness up to 12mm

- Machine 100kN, table size 3100x2500x1000mm, thickness up to 40mm

- Gantry machines Series LMA and LMB for serial industrial applications.

- Moving gantry machines Serie LMC for big size applications.

Certifications & Quality

EN ISO 3834-2: FR-0161-3834-2 in welding

EN 15085: FR-0161-CL1 welding in railway vehicle construction

ISO 9001 V 2015: Design-engineering, production engineering, project management and manufacturing of mechanically-welded automated assemblies

EN 1090-1: 2009 + A1:2011 EXC24

Application Fiels

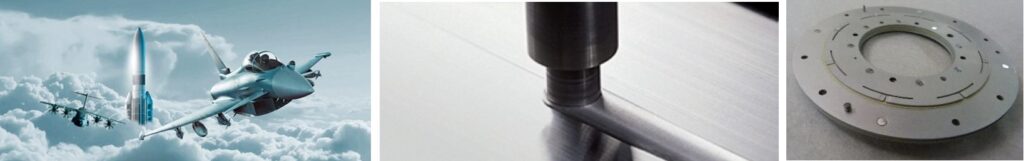

Defence, Aerospace

Transportation, Railway, Automotive

Energy, Nuclear

Other Industries