Hydroforming

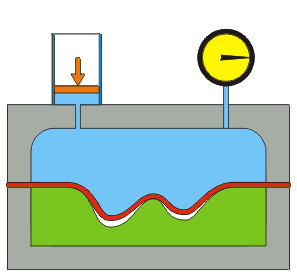

Hydroforming is a specialized type of die forming that uses a high pressure hydraulic fluid to press material into a die. High pressure hydraulic pumps then inject fluid at very high pressure above the plate or in a tube which causes it to expand until it matches the mold. The hydroformed part is then removed from the mold. Hydroforming allows complex shapes with concavities to be formed, which would be difficult or impossible with standard solid die stamping. Hydroformed parts can often be made with a higher stiffness-to-weight ratio and at a lower per unit cost than traditional stamped or stamped and welded parts. Virtually all metals capable of cold forming can be hydroformed, including aluminum, brass, carbon and stainless steel, copper, and high strength alloys.

Production possibilities:

- Part sizes within 1100 x 1600mm

- Draft depth up to 400mm