Spinning / Shear forming

Spinning is a modern forming technology for the production of seamless sheet metal parts. It is performed on machines which are built similar to lathes. Instead of a chuck the spinning tool is fixed. In place of a cutter a spinning roll is installed.

Shear forming

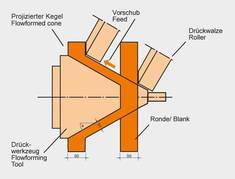

During this process a round blank is formed on a tool by reduction of wall thickness by means of a spinning roller, whereas the resulting end wall thickness is directly dependent on the angle of inclination of the tooling. The original round blank is clamped between tailstock and tooling. After plug in of the work spindle movement the spinning roller operates parallel to the axis according to the contour of the spinning chuck in the defined distance.

Spinning forming

The original round blank is clamped between tailstock and tooling. The work spindle starts turning. The roller is forming the material continuously until it finally fits on the flow-forming tool. The forming process takes usually place in several stages.

Generally almost all metallic materials can be formed by spinning as, for example:

|

|

Advantages:

|

|

Production possibilities:

- Round hollows up to 5000 mm diameter

- wall thickness up to 30 mm